In construction and engineering, precision is not just a preference; it’s a necessity. This is particularly true when it comes to steel projects, where the margin for error is minuscule, and the stakes are invariably high. Shop Drawing Services play a pivotal role in this meticulous process, ensuring that every beam, bolt, and joint is accounted for with unparalleled accuracy. The article examines the critical role that these services play in the meticulous design of steel projects, guaranteeing that ideas are not only realized but also carried out with an unshakable dedication to accuracy.

Understanding Shop Drawing Services

Have you ever wondered how large steel structures stand the test of time and weather, towering above us with unwavering strength? The answer lies in the precision of their construction, a process that begins long before the first beam is ever erected. At the heart of this meticulous process are Shop Drawing Services, a cornerstone in the construction of steel structures that ensures every detail is accounted for.

Shop Drawing Services acts as a comprehensive guide for fabricators and constructors, providing detailed diagrams and instructions for the fabrication and assembly of steel components. These drawings are rough sketches and highly detailed plans that specify dimensions, materials, and processes, ensuring that every component fits perfectly into the intended structure.

Key Aspects Include:

Detailed Diagrams: Precision in every line, showing how components fit together.

Material Specifications: Information on the types of steel and other materials required.

Fabrication Instructions: Step-by-step guides for fabricators, ensuring accuracy in the making of each part.

Accuracy: Ensuring that every component is accurately represented to fit perfectly into the overall structure.

Compliance: Adhering to relevant standards and building codes to ensure the structural integrity of the project.

The essence of these services is not just in guiding the construction but in translating architectural visions into feasible, structural realities. They bridge the gap between concept and construction, turning complex designs into tangible structures.

The Crucial Role of Steel Shop Drawings

Steel shop drawings are indispensable tools in the construction of steel frameworks. They provide fabricators and site engineers with precise information about how to fabricate, assemble, and install steel members. These drawings contain detailed specifications for all structural components, facilitating the accurate manufacturing and placement necessary for the structural integrity of the building.

Important Considerations:

Clarity: Drawings must be unambiguous to prevent errors in fabrication or assembly.

Standardization: Adherence to industry standards is essential for ensuring compatibility and structural soundness.

Collaboration: Effective communication among architects, engineers, and fabricators is key to aligning practical execution with design intent.

Steel shop drawing services bridge the gap between design and reality, serving as a comprehensive guide for the accurate realization of structural projects.

Ensuring Structural Integrity with Structural Steel Shop Drawing Services

Structural integrity is paramount in steel construction, and Structural Steel Shop Drawing Services is at the forefront of ensuring that every steel structure is designed and built to withstand the demands placed upon it. These services provide detailed drawings that include every aspect of the structural design, from the main framework to the smallest connections.

Critical elements to ensure integrity:

Precision: Drawings must be meticulously detailed to ensure that all components fit together as designed.

Compliance: Drawings should comply with all relevant construction codes and standards, guaranteeing the safety and durability of the structure.

Connection Details: The strength of a structure greatly depends on the quality of its connections. Detailed drawings must include comprehensive information on welding, bolting, and other connection methods.

These detailed services are indispensable for constructing safe, durable, and reliable steel structures. They ensure that the project is executed accurately, in line with both the design intent and regulatory requirements.

The Workflow for Excellence

The creation of shop drawings is a complex process that requires meticulous planning, collaboration, and execution to ensure the highest levels of accuracy and efficiency. Frequently called the Workflow for Excellence, this procedure involves a number of crucial phases intended to expedite the production and installation of structural steel components.

Steps in the Workflow for Excellence:

Initial Planning and Data Collection: The process begins with comprehensive planning, where project specifications, architectural designs, and engineering requirements are gathered. This stage involves understanding the scope, deadlines, and specific requirements of the project.

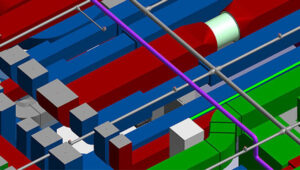

3D Modeling and Detailing: Using advanced CAD software, a detailed 3D model of the structure is created. This model includes all structural components, such as beams, columns, braces, and connections. The detailing phase focuses on creating detailed shop drawings from the 3D model, specifying dimensions, materials, and fabrication instructions.

Review and Approval: Shop drawings are then reviewed by the project’s engineering team, architects, and other stakeholders. This collaborative review ensures that the drawings meet all design requirements and comply with relevant standards and codes. Necessary revisions are made based on feedback.

Fabrication: With approved shop drawings, fabricators can begin the steel fabrication process. The drawings guide fabricators in cutting, welding, and assembling steel components with precision.

Installation: The final step involves the installation of fabricated steel components at the construction site. The detailed shop drawings ensure that each component fits perfectly into place, according to the overall design of the structure.

The Impact of Technology

The role of technology in the creation of shop drawings cannot be overstated. Advanced software and digital tools have revolutionized the way shop drawings are produced, improving accuracy, efficiency, and collaboration.

Key Technological Advancements:

CAD Software: Computer-Aided Design (CAD) software has been a game-changer, allowing for the precise drafting of complex structures. Software like AutoCAD and Tekla Structures enables the creation of detailed 3D models and shop drawings.

BIM: Building Information Modeling (BIM) technology goes beyond traditional CAD by offering a 3D model that includes time and cost dimensions. BIM facilitates better project management and coordination among all stakeholders, reducing errors and clashes.

Cloud Computing: Cloud-based platforms enable real-time collaboration among project teams, regardless of their geographical location. This technology ensures that everyone has access to the most up-to-date shop drawings and project documents.

Automation and AI: Artificial Intelligence (AI) and automation are increasingly being used to automate repetitive tasks, such as generating shop drawings from 3D models, improving speed and reducing human error.

Increased Accuracy and Efficiency: Technology reduces the likelihood of errors in shop drawings, saving time and resources by minimizing the need for revisions.

Enhanced Collaboration: Digital tools enable better communication and collaboration, ensuring that all project stakeholders are aligned.

Cost Savings: By improving efficiency and accuracy, technology can lead to significant cost savings throughout a project.

The integration of technology into the shop drawing process represents a significant leap forward for the construction industry, promising faster, more accurate, and cost-effective project completion.

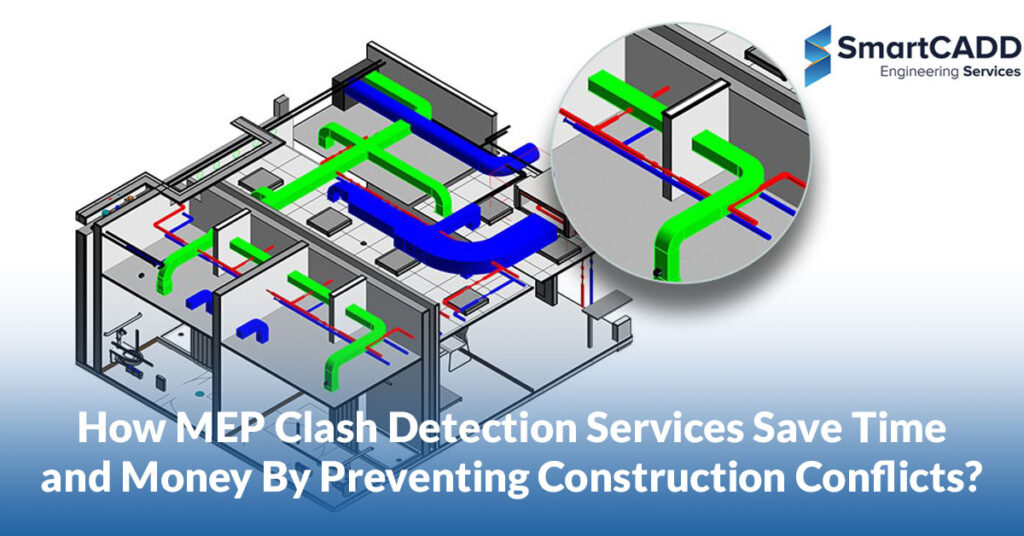

Conclusion: SmartCADD

In the end, the journey from a structural concept to a fully realized steel structure is complex and filled with potential pitfalls. Shop Drawing Services, through their detailed and precise nature, serve as the compass that guides this journey. By ensuring accuracy at every step, from fabrication to installation, these services are indispensable for achieving the perfection required in steel projects. SmartCADD recognizes the pivotal role of shop drawings in maintaining project integrity, advocating for a meticulous and technology-driven approach to every construction project.

FAQS

Shop drawings services involve creating detailed drawings that guide the fabrication and installation of steel components.

Shop drawings act as a roadmap, helping fabricators identify potential issues early and make necessary adjustments, reducing errors significantly.

By depicting the exact placement and connections of steel elements, shop drawings facilitate seamless coordination among architects, engineers, and contractors.